What is Aluminum Component Coolers

Aluminum Component Coolers

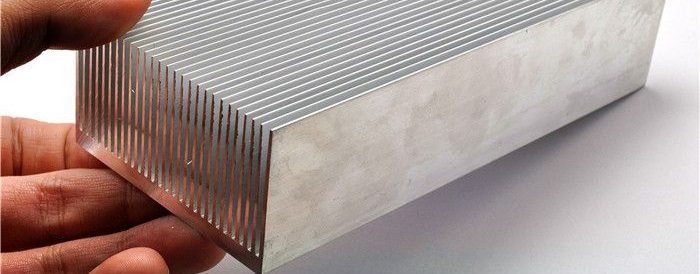

The parts that make up the electronic systems are called components. During use, these parts convert some of the energy they consume into heat, causing heat to accumulate on them. In order for the systems to work properly, these parts must be effectively cooled and prevented from reaching temperatures that will cause damage to the components. For this reason, component manufacturers try to design the covers of the components they produce in a way that prevents heat build-up. However, these designs often do not provide sufficient cooling. For this reason, Aluminum component coolers are developed for users to cool the components. Thanks to the aluminum profiles designed to increase the surface area, the necessary cooling is provided in the components.

How Do Aluminum Component Coolers Work?

Aluminum component coolers take advantage of the tendency to flow from where heat energy is high to where it is less. According to the second law of thermodynamics, if there is a temperature difference between the two systems, the heat passes from the warmer environment to the less hot environment. During use, the heat balance of the heated components deteriorates. The heat energy accumulated in the components cooled with the aluminum cooling profile passes to the colder aluminum blocks. The temperature control of the system is provided by being transported with the less warm air than aluminum blocks. The important thing here is that the speed of air transport should be equal to or higher than the heating rate of the component so that the heating of the component can be prevented. For this reason, solutions that will increase the surface area that will allow more contact with air are preferred in profile design.

How to Use Aluminum Component Coolers?

Aluminum component coolers are designed so that one surface provides maximum contact with the component. In this way, faster heat transfer from component to aluminum profile is provided. Nevertheless, thermal paste is used for the gaps that will cause non-contact between the component and the aluminum profile. Thermal paste are materials made to ensure uninterrupted heat conduction. The other side of the aluminum component coolers are produced in leaf shapes to increase the surface area and accelerate the air flow. In this way, heat energy is removed from the system by the way of the stone in a much larger surface area. When choosing an aluminum component cooler, a cooler capable of cooling at a higher speed than the heating rate of the system should be selected. By choosing a cooling profile block suitable for the component, it should be ensured that the components work without deterioration.